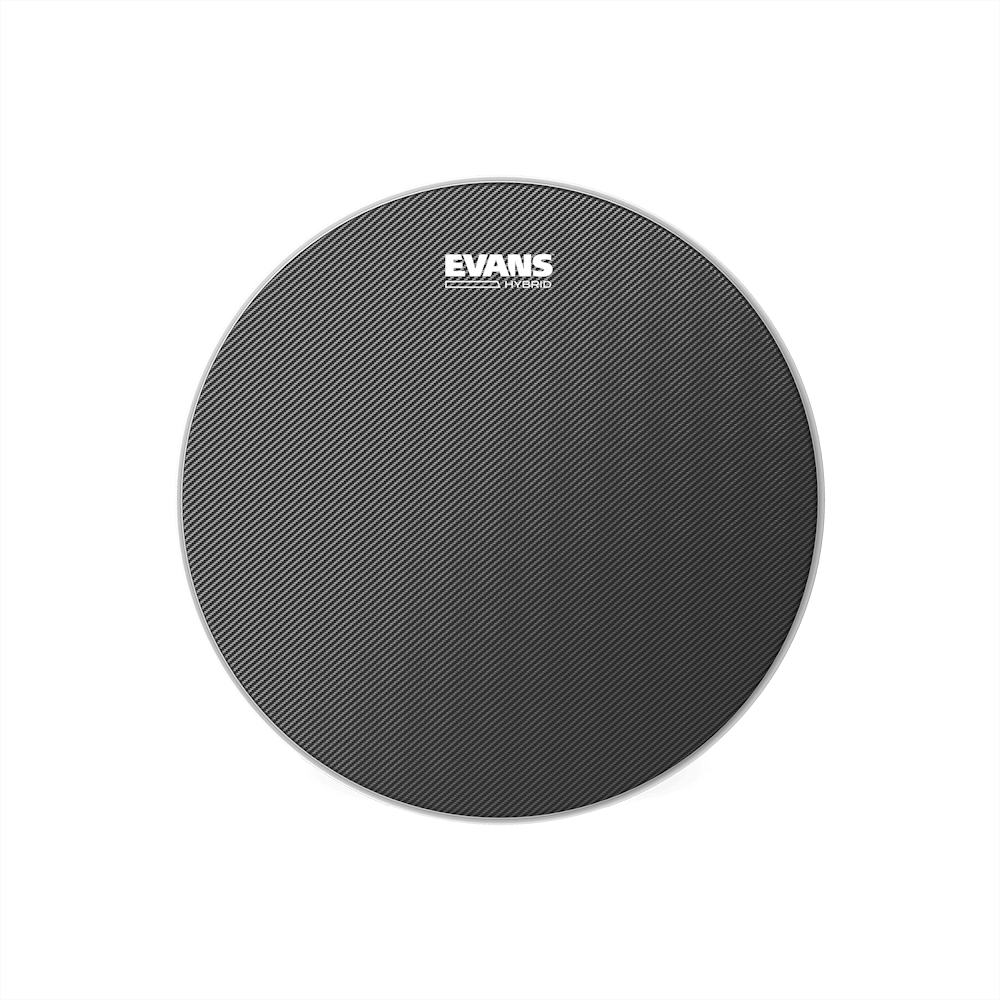

This is “The Last Pad” you should ever need. Dude, did you get The Last Pad? You need The Last Pad! After you have procure all other pads, you get this. This pad is our humble entry in to the “real rim and head tensioned drum pad”. As usual we are limiting our selves to reclaimed, recycled or sustainable materials to make our version - thus some limitations may be present. But we think this design is limitless, and modular, and has many applications for concert, jazz, brushes, marching, rope drum etc… We are selling this from the base up - we aren’t afraid to show under the hood :) You can buy replacement bases and Resistance Pucks as well as additional Insert Discs for different feels. If you have your own heads, just buy the base with hardware, two resistance discs, and you're good to go - we also sell heads and a high tension key for assembly. The insert discs have a bearing edge on them to help properly stretch the head as designed, as opposed to shoving material up in to the head. The 12 lug S-Hoop stick saving rim rests flush on the low tension side providing the resistance necessary for the opposing high tension side. The high tension side base is completely covered with 1/4” tire rubber, and when tightened, the rubber can be seen bowing out some under the insert disc. If it can hold up an SUV we assume it can hold back some kevlar. We added a handle, and stand cut outs, we would have added a snare sound, but it’s patented (of course). But we tried to cover all the bases with this one and feel this is an essential piece of practice equipment for the serious percussionist student and professional. One side for marching season, the other for everything else! Or one side for concert, one side for jazz, rope drum, rudimental…. etc.

Valchromat:

Most importantly to Beetle, the makers of Valchromat use eco-friendly and environmentally conscious production practices on an already reclaimed wood waste material. Valchromat is an innovative product that combines the natural features of wood with the brightness of color and, because of its unique flexibility, combines the beauty of textures and the best of engineering. Valchromat is not MDF. It is an evolution of the MDF. The added value of Valchromat comes not only from color but also from its distinctive composition and manufacturing process. It is a wood fiber panel colored throughout, where fibers are colored individually, impregnated with organic dyes and bonded together by a special resin which gives Valchromat unique physic and mechanical features.

Product Features:

Color Throughout: color remains, even after cut or machined. Does not require the use of paint. Do not require gluing an edge.

Weight-Resistant: high bending resistance

Easy to Machine: It is on average 30% stronger than standard MDF. Due to the addition of resins in the composition, it has a greater internal cohesion, which gives it a higher mechanical strength.

Non-toxic: Formaldehyde emissions are within limits set by European standards for wood-based materials.

Greater load resistance: It has a high bending resistance. Once again, its higher resistance capacity is related to its composition and manufacturing process.

Tool Friendly: The panels, after machined, require little or no sanding, reducing labor costs and facilitating the finishing process.

Moisture Resistant: Suitable for indoor applications but can be used in protected outdoor applications, in which case it is necessary to varnish the boards on all surfaces and edges.

Valchromat does not source wood from:

Forest areas where civil or traditional rights are violated

Forest areas of high conservation values threatened by forest management activities

Genetically modified trees (GMOs)

Forest areas exploited illegally

Forest areas resulting from the conversion of natural forests to plantations or non-forest uses

Their manufacturing processes include:

Manufacturing without waste: Valchromat’s production is aimed at reducing, or even eliminating environmental impact. All waste and bark resulting from the initial processes are reused to fuel the factory's steam boiler.

Self-sufficiency on thermal energy: Valchromat’s manufacturing plant generates enough biomass to sustain its thermal energy requirements, without burning any fossil fuels.

100% Recyclable